Air pollution has become a major concern worldwide, affecting both our health and the environment. The use of air filters plays a crucial role in combating this issue. In this article, we will discuss the importance of air filters, the manufacturing process, innovations in the field, and the impact of air filter manufacturing on reducing the environmental pollution. Finally, we’ll look at the future of air filter manufacturing and its potential to further help mitigate air pollution control well.

Air pollution is a major concern that affects both the environment and human health. It has been identified as one of the leading causes of respiratory diseases, heart problems, and even cancer. While there are many sources of air pollution, ranging from industries to vehicles, one solution is the use of air filters.

Air filters work by removing harmful particles and contaminants from the air we breathe. The HEPA air purifier factory, they purify the air by air purification manufacturers. They play a vital role in reducing environmental pollution while improving indoor air quality. In this blog post, we will dive deeper into how air purification and filter manufacturing can help reduce environmental pollution and its advantages.

The Importance of Air Filters

Air filters play a crucial role in maintaining the quality of indoor air. They work by trapping airborne particles that can cause respiratory problems and other health issues. These pollutants include dust, pollen, pet dander, smoke, and mould spores.

Using air filters greatly reduces these contaminants in our environment; this is especially important for people with allergies or asthma. It also helps to prolong the lifespan of your HVAC system by keeping it free from debris buildup.

Moreover, air filters help to reduce outdoor pollution from entering our homes or workplaces. This is because they trap harmful particles before they enter the building’s ventilation system.

Additionally, using high-quality air filters can contribute to energy savings since systems don’t have to work as hard when there’s less dirt and debris present in their components.

Investing in air pollution control equipment and filter manufacture technology provides an effective solution towards reducing environmental pollution while significantly improving indoor air quality.

Health Benefits

The manufacturing of air filters plays a significant role in reducing the environmental pollution. Through the use of efficient and effective air filters, contaminants such as smoke, dust and other harmful particles can be removed from the atmosphere before they get to our lungs.

Apart from protecting our environment, clean air also has numerous health benefits. Research indicates that people who breathe polluted air experience respiratory problems such as asthma attacks, lung cancer and heart disease. With clean indoor and outdoor air supply due to the installation of high-quality air filters, we can reduce these adverse health effects significantly.

It is evident that manufacturing quality air filters to reduce environmental pollution is an essential aspect of human life on Earth. Not only does it benefit our environment but also promotes healthy living conditions for us all. Therefore let’s embrace its importance by prioritizing clean energy production practices that promote better human well-being!

Environmental Protection

By manufacturing air filters that reduce environmental pollution, we take a significant step towards protecting our planet. The benefits of reducing pollution are manifold; it helps to minimize the impact of climate change and preserve biodiversity. By breathing cleaner air, we can lead healthier lives and enjoy better well-being.

It is essential for everyone to play their part in promoting a sustainable future by supporting the manufacture and use of air filters that decrease the environmental pollution. As more individuals become aware of the importance of clean air, there will be an increased demand for these products.

The manufacture of air filters to reduce environmental pollution is crucial in protecting our environment and promoting healthy living standards. We must all work together as responsible citizens to support this cause because clean air means a better tomorrow for ourselves and future generations.

Air Filter Manufacturing Process

Air filters play a vital role in reducing environmental pollution and improving overall health. The manufacturing process is complex, but the end result is worth it. By using quality materials and advanced technology, manufacturers can create effective air filters that help protect our planet.

Whether you are concerned about your personal health or the environment as a whole, investing in high-quality air filters is an excellent way to make a difference. So next time you consider buying an air filter for your home or business, remember how important this small device can be in protecting our world from harmful air pollutants.

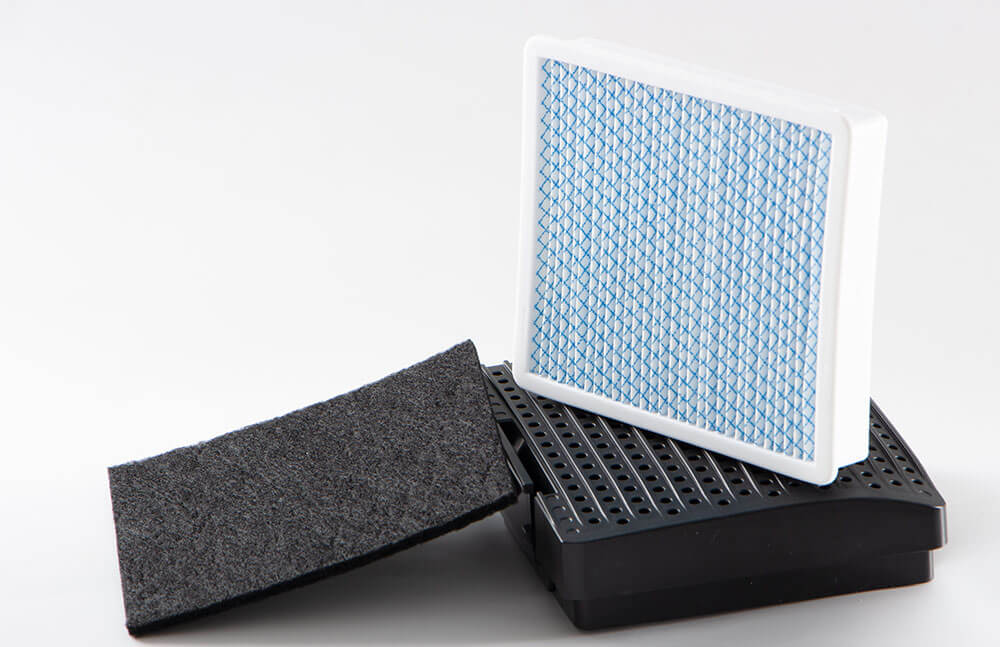

Materials Selection

Air filter manufacture is an essential process in reducing the environmental pollution. It not only improves the quality of the air we breathe but also has significant health benefits for individuals with respiratory problems. Air filters can be made from various materials such as cotton, fiberglass, and synthetic fibers like polyester and polypropylene.

The choice of material used in manufacturing depends on several factors such as cost-effectiveness, energy efficiency, durability, and overall effectiveness in capturing pollutants. Moreover, some manufacturers may opt to use recycled or sustainable materials to reduce their carbon footprint.

Filter Design

The final step for an air filter manufacturer is designing the filter. This process involves creating a layout for the filter that will allow it to trap as many pollutants as possible while still allowing air to flow freely through it.

Filter design is an important aspect of air filtration because a poorly designed filter can not only fail to protect our health and environment but also decrease airflow, reducing HVAC system efficiency.

Air filters are essential components of our daily lives. They help protect us from harmful pollutants and contaminants, ensuring that we breathe clean and healthy air. HEPA filter manufacturers play a critical role in developing these filters by selecting appropriate materials, following proper manufacturing processes, and designing effective air filtration systems themselves.

Production Methods

Once the design is finalized, air filter manufacturing can begin. There are several production methods that manufacturers use to create high-quality and effective air filters.

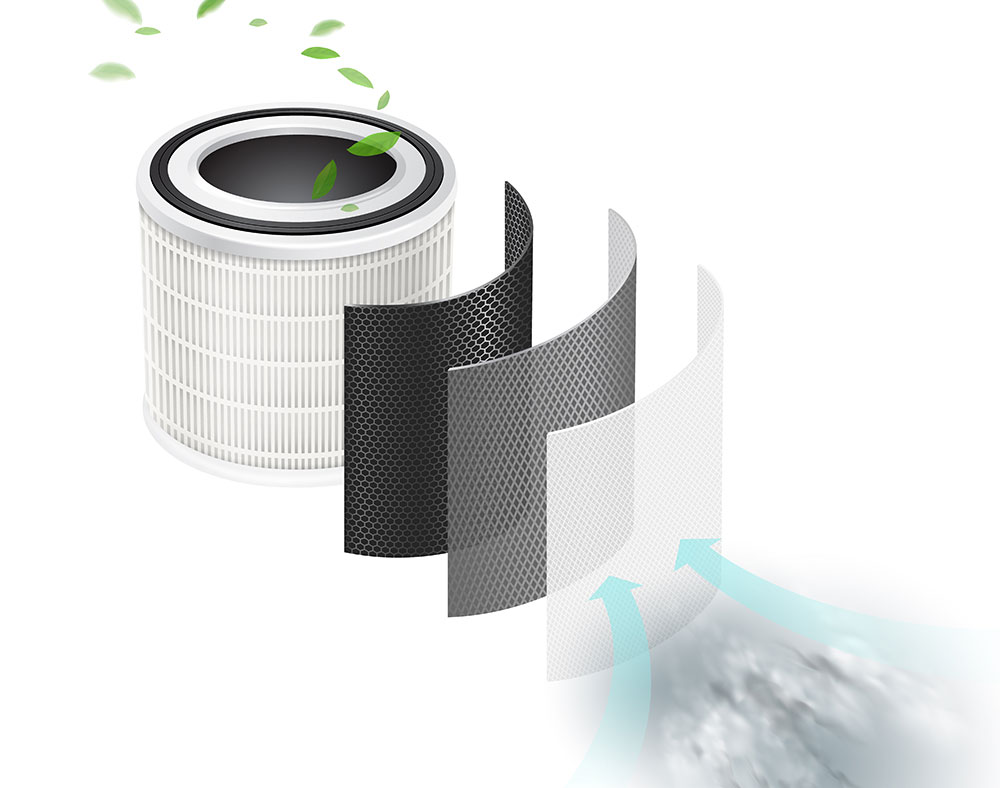

One common method is called pleating, where a sheet of filter media is folded back and forth like an accordion until it forms a sealed edge on one side. This creates many layers in a small space, maximizing surface area for filtering while maintaining airflow.

Another approach is electrostatically charged fibers, which attract airborne particles and trap them within the filter material. This technique can be combined with other filtration methods for even better performance.

Innovations in Air Filter Manufacturing

Innovations in Air Filter Manufacturing are continuously being developed to improve the effectiveness of air filters in reducing the environmental pollution. One such innovation is the use of nanofiber technology, which provides superior filtration efficiency and longer filter life compared to traditional methods. Another development is the integration of smart sensors that monitor air quality and adjust the filtration rate accordingly.

It’s clear that air filter manufacturing plays an essential role in reducing environmental pollution and improving overall health. The proper selection of materials, design, and production methods can significantly impact the effectiveness of an air filter. With continued advancements in technology, manufacturers have more opportunities than ever before to create effective solutions for cleaner air.

Advanced Filtration Technologies

As environmental concerns continue to escalate, the demand for air filters that can reduce pollution levels is on the rise. Manufacturers are stepping up their game with advanced filtration system technologies that offer better efficiency and performance.

From electrostatic precipitators to activated carbon filters and even nanofiber membranes, these advancements in air filter technology have made it possible to remove a wide range of pollutants from the air we breathe.

The benefits of these technologies go beyond just environmental protection against poor air quality; they also promote energy efficiency by reducing the need for ventilation systems to work harder than necessary. All in all, these innovations provide an effective solution for combating air pollution while supporting sustainable development.

Sustainable Manufacturing Practices

Sustainable manufacturing practices are crucial for reducing the environmental impact of air filter manufacturing. By implementing sustainable methods, manufacturers can reduce waste and energy consumption while also promoting worker safety and health.

One example of sustainable manufacturing is using recycled materials in the production process. Manufacturers can source recycled plastics or metals to create their filters instead of relying solely on new raw materials.

Another important aspect of sustainability is reducing greenhouse gas emissions during production. This can be accomplished by optimizing energy use through efficient equipment and processes, as well as investing in renewable energy sources such as solar or wind power.

Ensuring that workers have safe working conditions and fair wages is essential for a truly sustainable manufacturing process. Companies that prioritize these values not only benefit their employees but also demonstrate a commitment to social responsibility.

Impact of Air Filter Manufacturing on Pollution

As we have seen, air filters play a vital role in reducing environmental pollution by removing harmful particles from the air we breathe. However, it is important to consider the impact of air filter manufacturing on air pollution control systems by itself.

While air filters help reduce pollutants in the atmosphere, their production can also contribute to pollution if not done sustainably. That’s why it’s crucial for manufacturers to adopt sustainable practices that minimize waste and emissions during production.

Thankfully, many companies are already making strides towards sustainable manufacturing processes, such as using eco-friendly materials and implementing energy-efficient facilities. In doing so, they not only reduce their ecological footprint but also set an example for others to follow suit.

Reducing Emissions

By reducing the emissions produced by residential ventilation systems and by air filter manufacturing, we can significantly reduce environmental pollution. This can be achieved through sustainable manufacturing practices and the use of advanced filtration technologies. As individuals, we can also play a role in reducing pollution by regularly changing our HVAC filters at home and using environmentally-friendly products.

The importance of air filters cannot be overstated when it comes to protecting our health and preserving the environment. By understanding the air filter manufacturing process, the materials used, and the production methods employed, we can make informed decisions that promote sustainability while still providing clean air.

Energy Efficiency

Air filter manufacturing plays a significant role in reducing environmental pollution. By selecting the appropriate materials and production methods, manufacturers can design filters that improve indoor air quality and protect our environment. Advanced filtration technologies allow for even more effective air cleaning while sustainable manufacturing practices reduce waste output and energy consumption.

One of the most important considerations is energy efficiency. With rising concerns about climate change, it’s crucial to minimize the impact of manufacturing processes on the environment. Energy-efficient equipment is now widely available, making it easier than ever for manufacturers to reduce their carbon footprint.

Future of Air Filter Manufacturing

As we continue to face the challenges of environmental pollution, air filter manufacturing plays a crucial role in mitigating this issue. The future of air filter manufacturing is promising as new and innovative technologies are being developed to enhance filtration efficiencies while also reducing the impact on the environment.

In order to reduce emissions and improve energy efficiency, sustainable manufacturing practices are being implemented by many manufacturers. Advanced automation systems and advanced materials selection methods are also being adopted for efficient production processes.

As consumers become more environmentally conscious, there will be an increasing demand for high-quality air filters that provide superior protection against pollutants. This will lead to further investment in research and development of new filtration technologies that offer higher levels of performance while minimizing their carbon footprint.

The future of air filter manufacturing is bright, as it has the potential to play a significant role in improving our environment’s overall health. By continuing to innovate and adopt sustainable practices, HEPA air filter manufacturers can contribute positively towards reducing environmental pollution.

Smart Air Filters

As we move towards a more sustainable future, smart air filters are proving to be the next big thing in indoor air pollution filtration technology. These filters are equipped with sensors that detect changes in air quality and adjust their filtering capacity accordingly. They can also communicate with other smart devices in the home or office, providing real-time monitoring of indoor air quality.

Smart air filters not only reduce energy consumption but these air pollution control technologies also provide custom solutions for individual needs. They allow us to monitor and manage our indoor environment while minimizing our impact on the environment.

Biodegradable Materials

As we move towards a more sustainable future, HEPA filter manufacturers have begun to explore the use of biodegradable materials in their production processes. These materials can break down naturally over time and do not contribute to environmental pollution.

There are already some companies that produce air filters made from biodegradable materials such as hemp, coconut fiber, and bamboo. These filters are just as effective at capturing pollutants as traditional filters but are much kinder to the environment.

As consumers become more environmentally conscious, there will likely be an increase in demand for these types of eco-friendly air filters. This shift towards sustainable manufacturing practices is an important step in reducing our impact on the planet and protecting our health.

Air filter manufacturing plays a crucial role in reducing environmental pollution by improving indoor air quality and reducing outdoor emissions. As technology advances and new innovations emerge, we can expect even better filtration solutions that protect both our health and the environment. By adopting sustainable manufacturing practices like using biodegradable materials, we can work towards a cleaner future for ourselves and generations to come.

Air Filter Manufacture to Reduce Environmental Pollution

Air filters are devices that work by trapping harmful particles, such as pollen, dust, and smoke from the air. The filter can be made of various materials like paper or foam, but its primary function is to remove pollutants from the air we breathe.

Manufacturing high-quality air filters plays a vital role in reducing environmental pollution since they remove impurities before releasing them into the atmosphere. By using these filters in our industrial facilities, plants and vehicles, we prevent toxic substances from being released into our atmosphere.

What is an air filter?

An air filter is a device that removes impurities from the air. It is commonly used in HVAC systems and automobile engines to improve indoor air quality and reduce emissions. Air filters can be made of various materials such as fiberglass, pleated paper, or foam.

The primary function of an air filter is to trap dust, pollen, smoke particles, pet dander and other pollutants before they enter your lungs or the engine’s combustion chamber. The filter captures these harmful substances effectively preventing them from circulating through the environment.

Types of air filters

When we talk about air filters, it’s important to understand the different types of industrial air filters that are available. Each type serves a unique purpose in reducing environmental pollution.

One of the most common types is the mechanical filter, which captures pollutants through a physical barrier, such as mesh or fibres. These filters can remove larger particles like dust and pollen from the air.

Another type is an electrostatic filter, which uses static electricity to attract and trap particles. This type of filter is effective at removing smaller pollutants like smoke and pet dander.

Activated carbon filters use activated carbon to absorb gases, odours, and chemicals from the air. They are commonly used in areas with high levels of traffic or industrial emissions.

UV-C light filters use ultraviolet radiation to kill bacteria and viruses in the air. These types of filters are especially useful for people with allergies or respiratory conditions.

Understanding each type of air filter can help you choose one that suits your specific needs when it comes to reducing the environmental pollution.

How air filters help reduce environmental pollution

Air filters are an essential tool in reducing environmental pollution caused by airborne particles. These tiny particles can include dust, dirt, pollen, and even harmful chemicals. Without air filters, these pollutants could circulate freely throughout the atmosphere and cause harm to both humans and the environment.

Air filters work by capturing these small particles as they pass through the filter material. This prevents them from being released into the air and allows for cleaner, healthier breathing conditions.

Advantages of using air filters

Using air filters in various industries and households has several advantages apart from reducing the environmental pollution. Here are some of the key benefits:

Firstly, air filters help to improve indoor air quality by trapping and removing harmful pollutants such as dust, allergens, mold spores, and bacteria. This is especially important for people who suffer from allergies or respiratory conditions.

Secondly, using air filters helps to maintain the efficiency of heating and cooling systems by preventing dirt and debris buildup on components such as coils and motors. This can lead to lower energy bills due to improved system performance.

Thirdly, air filters can also extend the lifespan of equipment such as HVAC units or industrial machinery by protecting them from damage caused by airborne particles.

Conclusion

Air filter manufacturing plays a vital role in reducing environmental pollution by improving indoor air quality and capturing pollutants from industrial processes and vehicles. Innovations in traditional air filtration systems and technologies and sustainable manufacturing practices have the potential to further reduce pollution and improve our health and the environment. As technology advances, we can expect to see even more effective and eco-friendly air filters that contribute to a cleaner, healthier future for all.

Breathe cleaner air with hokocare.com’s high-quality air filters! Our company is a leading air filter manufacturer, committed to providing you with top-of-the-line products that improve your indoor air quality and help you maintain a healthy and comfortable environment.

FAQs

Why are air filters important for our health and the environment?

Air filters help improve indoor air quality by removing harmful particles, protecting us from respiratory issues and allergies. They also help reduce environmental pollution by capturing pollutants from industrial processes and vehicles.

What materials are commonly used in air filters?

Common materials include activated carbon, HEPA filters, and electrostatic filters. The choice of material depends on factors such as cost, durability, and filter performance.

How do innovations in air filter manufacturing help reduce pollution?

Innovations such as advanced filtration technologies and sustainable manufacturing practices improve filter performance, reduce waste, and minimize energy consumption, all of which contribute to reduced pollution.

What are smart air filters?

Smart air filters incorporate sensors and advanced technology to monitor air quality, filter performance, and energy consumption. This allows for real-time data analysis and more efficient filter maintenance.

What are biodegradable materials in air filters?

Biodegradable materials in air filters are designed to decompose naturally after use, minimizing the environmental impact of filter disposal and contributing to a more sustainable future.